A short explanation of the differences:

Calibration ISO17025 certificate

vs. Test ISO 17025 certificate

vs. Factory (WERKS) certificate

Table of Contents

Introduction

In this article a short explanation of the differences between factory (WERK) calibrations, DAkkS ISO17025 calibrations and DAkkS ISO17025 tests is given.

I. Procedure

I.a. Calibration

During a calibration, the deviation of the measured variable of a measuring device is determined. The measurement is usually performed on a standard artefact, traceable to national standards, and measured under defined environmental conditions. The result and associated measurement uncertainty are recorded on a calibration certificate.

Calibrations performed by Gigahertz-Optik generally comprise adjustment AND calibration, whereby the calibrated measured variable is traceably aligned with national standards at the time of calibration.

I.b. Adjustment

DIN 1319-1 defines adjustment as: “The setting and aligning of a measuring device to eliminate systematic measurement deviations to the extent necessary for the intended application. Adjustment requires an intervention that permanently alters the measuring device.” During the adjustment process, the measurement value of a measuring device is set to the known value of a reference object (e.g. by comparing with a measurement standard). The measuring device must be operated under prescribed or agreed reference conditions.

Adjustment renders a previous calibration and/or test invalid. The measuring device must afterwards be calibrated or inspected again to make sure its results are traceable.

I.c. Test

During a test, the deviation of the measured variable of a measuring device is determined. The comparison is also usually carried out with a standard traceable to national standards under defined environmental conditions. The result and associated measurement uncertainty are recorded on a test certificate.

No changes to the device are made. No adjustment takes place.

II. Laboratory types

II.a. Calibration laboratory

DAkkS-accredited (formerly DKD) calibration laboratories accredited in accordance with DIN EN ISO 17025 receive an accreditation for specific measurement quantities.

II.b. Test laboratories

DAkkS-accredited test laboratories according to DIN EN ISO/IEC 17025 receive their accreditation for specified measurement and test procedures.

II.c. Calibration laboratory vs. test laboratory

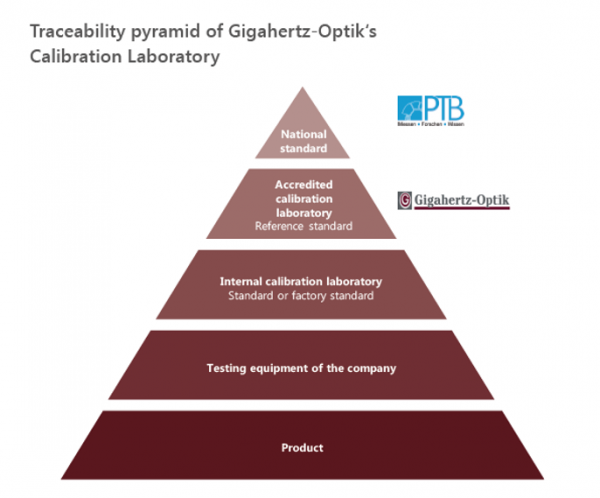

A DAkkS calibration laboratory can adjust and calibrate accredited measurement quantities. Calibrated devices can be listed within a continuous DAkkS traceability chain. As such, DAkkS calibration certificates meet the highest standards. DAkkS-accredited calibration and test laboratories fall directly under the NMIs (national metrology institutes, e.g. PTB).

The DAkkS test laboratory uses accredited procedures to check the correctness of a measurement result. This means that a device that passes the test provides correct measurement results when using the accredited measurement procedure, within the set uncertainties. These results can be traced back to national standards. The inspected device cannot be used as a reference standard for the calibration of another product at another calibration laboratory within the DAkkS traceability chain. However, test equipment with a DAkkS test certificate can be used as a DAkkS-traceable measuring device for measuring purposes.

III. Certificates

III.a. Factory calibration certificate

A factory (WERKS) calibration is subject to the laboratory’s self-imposed obligation to traceability. With these calibrations, Gigahertz-Optik commits itself to traceability in compliance with standards, documented laboratory processes, and expert calculations of calibration uncertainties. As such, factory (WERKS) calibrations by Gigahertz-Optik are based on DIN EN ISO/IEC 17025. The internal traceability to the calibration standards of Gigahertz-Optik calibration laboratories, which are monitored by the accreditation body, has provided additional control of the calibration processes or factory calibrations for many years. This competence offers crucial benefits to customers.

At Gigahertz-Optik, factory calibration certificates can be recognized by the word “WERK” printed onto the calibration mark.

III.b. DAkkS certificates

DAkkS-accredited laboratories are subject to monitoring by the accreditation body and continuous external control. Conformity with the DIN EN ISO/IEC 17025 standard is ensured.

III.b.1 DAkkS calibration certificate

DAkkS calibrations are, according to the national standards of NMIs (national metrology institutes), the highest level of standard in the calibration chain. Only calibration laboratories accredited according to DIN EN ISO/IEC 17025 are allowed to perform them. As such, traceability to national standards is always guaranteed with DAkkS accreditation.

It is a requirement of DIN EN ISO 9000 / 9001 standards that test equipment must be calibrated in a traceable manner. A DAkkS accredited calibration meets this requirement unconditionally. The calibration certificates are internationally valid without further proof. These calibration certificates can be included into a traceability chain that can be traced back to the DAkkS.

At Gigahertz-Optik, DAkkS calibration certificates can be recognized by the DAkkS certificate number for the DAkkS calibration laboratory “D-K-15047-01-00” printed onto the calibration mark. Furthermore, the DAkkS logo and the DAkkS certification number are listed.

III.b.2 DAkkS test certificate

Only test laboratories accredited in accordance with DIN EN ISO/IEC 17025 are allowed to perform DAkkS tests. The traceability of the test equipment used for testing to national standards is also always guaranteed for test certificates by the DAkkS accreditation.

At Gigahertz-Optik GmbH, DAkkS test certificates can be recognized by the certificate number. The DAkkS logo with DAkkS certificate number for the DAkkS test laboratory “D-PL-150401-00” is also specified. Many Gigahertz-Optik calibration products include preconfigured Factory (WERKS) calibration from the DAkkS test laboratory.

III.c DAkkS calibration certificate vs. DAkkS test certificate

A DAkkS calibration certificate attests to the traceability of a measured value to a national standard. Test equipment with a DAkkS calibration certificate can be included into a DAkkS traceability chain.

A DAkkS test certificate attests to the correctness of a measurement result with the specific measurement procedure used with its traceability to national standards. Test equipment with a DAkkS test certificate can be used as DAkkS-traceable measuring equipment for measurement tasks.

DAkkS calibration certificates and DAkkS test certificates are accepted internationally without further proof, therefore offering the customer enormous benefits.

III.d. DAkkS calibration certificate vs. Factory calibration certificate

With DAkkS traceability, only DAkkS calibration certificates are allowed to be included into the calibration chain. Factory (WERKS) calibration certificates, on the other hand, are subject to the self-imposed requirements of the laboratory and are not accepted during the accreditation.

There are, however, major variations in the quality of factory (WERKS) calibrations. Gigahertz-Optik operates in an exemplary manner, as the offered traceability of factory (WERKS) calibrations is always based on DIN EN ISO/IEC 17025, even if these measurement values are not registered with the DAkkS. These WERKS calibrations have been successfully used for over 25 years with great acceptance among our customers.

Furthermore, there are measurement quantities and geometries to which DAkkS accreditation cannot apply, as these are not offered by the national institutes. In these instances, the factory (WERKS) calibration certificate of a laboratory with such a high degree of individual responsibility offers a first-class alternative.

The increased requirements of an initial accreditation according to DAkkS and the subsequent maintenance of the accreditation as a DAkkS calibration and test laboratory come with additional costs. These can exceed the costs of the previous factory (WERKS) calibrations. In all cases where these higher coststs are unattractive to our customers, we continue to offer factory (WERKS) calibration certificates as a high quality alternative.

Assessment in accordance with IATF 16949:2016

IATF 16949:2016 specifies, in accordance with our legally non-binding assessment, that external laboratories be accredited in accordance with ISO/IEC 17025. In addition, the issued test or calibration certificates must include the marking of a national accreditation body such as DAkkS. Accordingly, both DAkkS test and calibration certificates meet this demand.

Summary

The optimal choice of calibration (i.e. factory (WERKS), DAkkS test or DAkkS calibration) depends on the intended use and the resulting requirements of the product. We will gladly advise you on your specific circumstances.