UV Radiation Measurements

UV radiation - useful applications

Ultraviolet radiation (UV) is widely used in many industrial processes, primarily for curing, purification, sterilization and lithography. The accurate UV measurement of such high-energy UV radiation sources requires particular demands on the design and calibration of suitable instrumentation or called UV Meters. Gigahertz Optik GmbH offers a comprehensive product range of temperature stable and robust instruments and measurement accessories for measuring high energy ultraviolet radiation, a selection of which are presented in the application examples on this page.

Additionally, particular UV measurement solutions are also presented in the following application categories:

Irradiance Measurement of High-Power UV Light Sources (UV Curing)

High intensity UV radiation is present in a range of applications. For example, high power UV light sources are widely used for UV curing which presents a number of measurement challenges that need to be addressed.

Controlling the exposure of work pieces to UV energy (time and intensity) is essential in the curing processes widely used for coating, printing, adhesives, encapsulants and potting compounds. To monitor and adjust the UV energy, the irradiance needs to be measured as close as possible to the surface of the irradiated parts in order to represent the same exposure. Successful curing requires the correct dose of UV at the wavelengths appropriate for the particular material.

A suitable radiometer must also be able to withstand a high temperature environment or have the option to offer correction for temperature effects.

Reduced Measurement Uncertainty for UV-A, UV-B and UV-C Radiometers

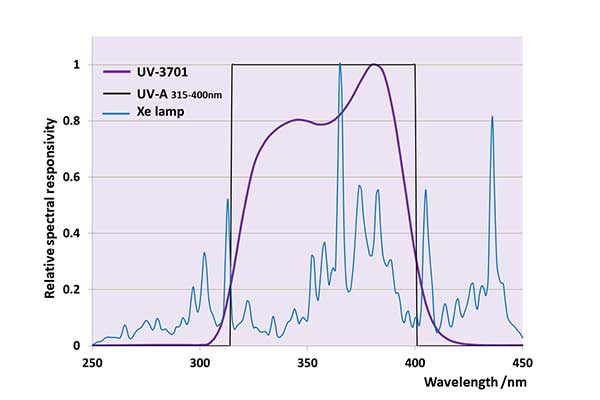

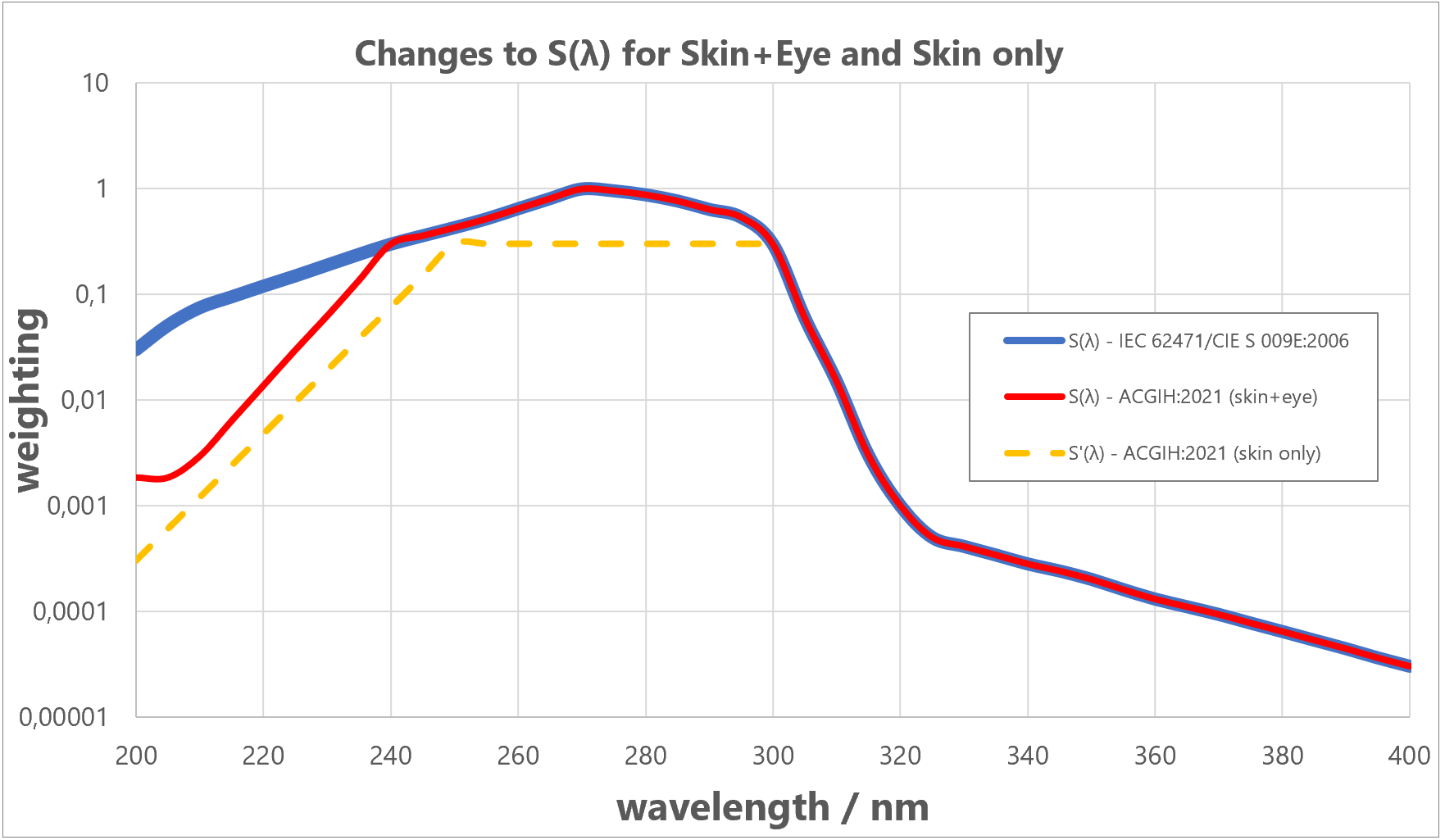

UV radiometers do not come in ‘one size fits all’ format. They may be required to have a flat spectral response over specific spectral bands (e.g. UV-A, UV-B and UV-C) or to match particular actinic spectral functions (e.g. ICNIRP or erythema). UV radiometers are typically constructed from a photo-detector and filter combination, often with an entrance optic such as a diffuser for good cosine response.

What is common to all filter-corrected radiometer designs is that their spectral responsivity function will never perfectly match the target specification and further production-related tolerances will also arise. These inevitable spectral mismatches introduce measurement uncertainties. Their magnitude depends not only on the deviations of the spectral responsivities, but also on the relative spectral power distribution of the radiation source being measured. The technical report CIE 220: 2016 [1] presents a methodology for determining the expected measurement uncertainty due to spectral mismatch.

We provide UV radiometers with this special calibrations to allow accurate measurements of different light sources.

Irradiance Measurement of High-Power UV LEDs

UV LED lamps are being enthusiastically developed and adopted as alternatives to the medium pressure mercury lamps traditionally used for UV curing processes. UV LED curing offers several potential advantages including reduced power consumption, less heat generation, instant switching, longer lifetimes, as well as the environmental benefit of being mercury-free. UV radiometers are widely used to monitor and control the UV exposure (or ‘dose’) from high-intensity gas discharge lamps on work surfaces. However, UV LED devices emit a narrow spectrum of radiation (typically ±10 nm), whereas mercury lamps have a much broader spectral distribution. This has significant implications for the design and calibration of radiometers if they are to be suitable for measuring the irradiance of UV LED curing equipment.

The UV radiometers produced by Gigahertz-Optik GmbH generally have a broadband spectral responsivity function resulting from the combined characteristics of the photo-detector and filter.

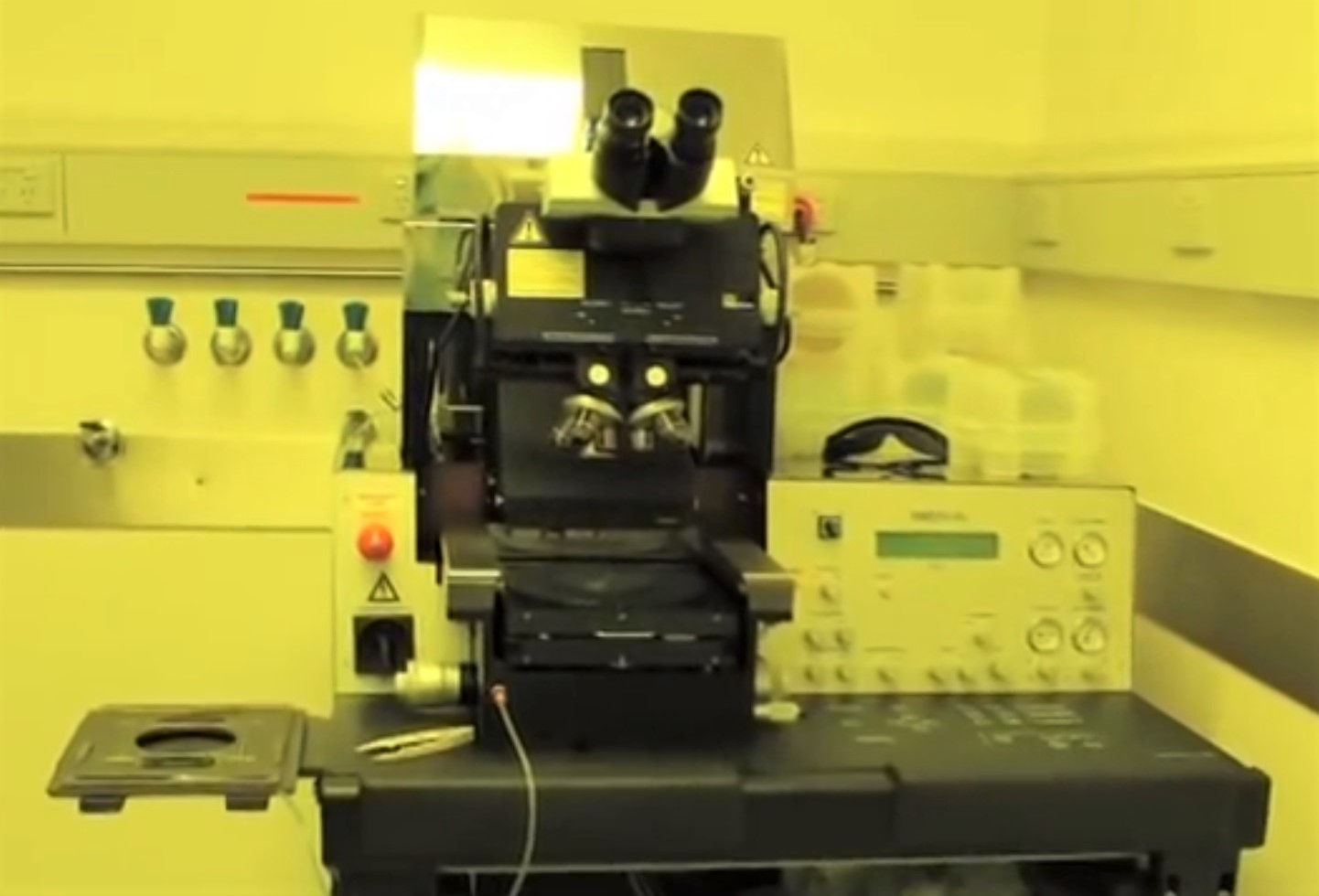

UV measuring devices for mask aligners (lithography)

We offer UV radiometers with filter-corrected detectors for classical spectral broadband UV lamps such as medium-pressure mercury vapor lamps or low-pressure lamps at mask aligners. Here we rely on decades of experience with major customers in this field. Due to the increasing use of LED light sources, we also offer UV radiometers for measuring the irradiance of different LED wavelengths as well as spectral measuring systems (spectroradiometers). The advantage of UV radiometers results from their favorable price-performance ratio, the flat design, the short measuring times and their robustness. Spectral radiometers are more independent of the LED spectral range.

Standards about Germicidal UV Radiation

Most standards relate to the potential hazard of UVC sources (photobiological safety) rather than to the germicidal effectiveness (germicidal efficacy) of UVC light sources. In general, they are based on ICNIRP guidelines on the limits of exposure to ultraviolet radiation, published in HEALTH PHYSICS 87(2):171-186; 2004.