Image Sensors and Cameras Testing and Calibration

Application examples for image sensors and much more

Testing, calibration or characterization of devices such as image sensors, industrial cameras, hyper-spectral imaging sensors and optoelectronic detectors requires the use of light sources with highly uniform light distribution. Gigahertz Optik GmbH produces a wide range of homogeneous (uniform) light sources with integrating spheres and LED panels with which the uniformity and performance of image sensors and industrial cameras can be determined. Some application examples are presented on this page.

Sensing & Remote Sensor Calibration

Remote sensors and optical sensors in general including cameras, industrial vision and earth observation systems like satellites need sophisticated device characterizations like linearity, white balance, bad pixel correction or calibration. This starting in R&D projects all the way to series production and quality processes. Especially nowadays where data driven technologies play an important role a many field of application.

We offer standard solutions and additional we have the capability for designed customized solutions and OEM solutions perfectly design to your needs. Customer centered product design connected with Know-how and ISO 17025 capabilities makes us your partner in order to be successful.

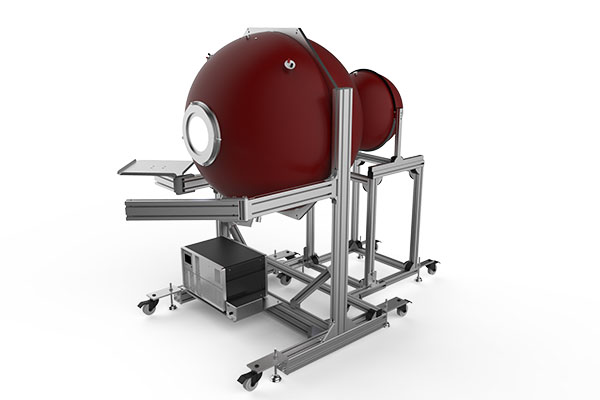

Uniform Integrating Sphere Light Sources for High Dynamic Range Test and Calibration of Imaging and non-Imaging Devices

To measure the sensitivity, linearity and non-uniformity of imaging sensors, a test setup with a reference light source is required which homogeneously irradiates the test specimen. Integrating sphere light sources with quasi monochromatic emission spectra can be used for qualifying grayscale and color sensors and camera systems. However, for the characterization of imaging sensors and systems required for more demanding photometric and spectroradiometric measurement tasks, light sources with a continuous emission spectrum are necessary. The standard illuminant for such applications is the quartz halogen lamp.

The only suitable light source with a broadband continuous emission spectrum from ultraviolet to infrared is the quartz-halogen lamp. Their spectral emission curve closely matches that of a black body over the wavelength range from 250 nm to 2500 nm. Therefore, a quartz-halogen lamp’s color temperature is approximately the operating temperature of the lamp’s filament.

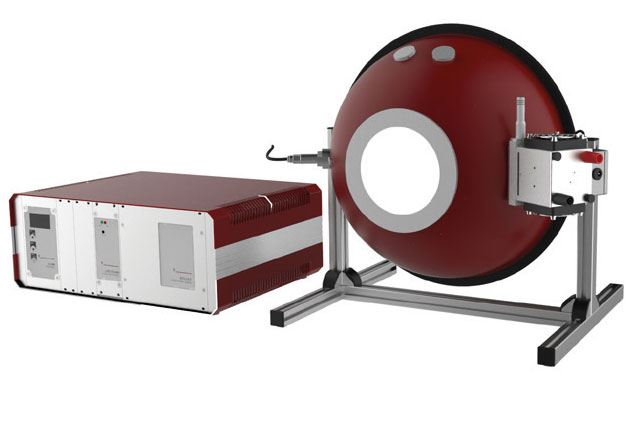

Reference Light Source for EMVA 1288 Testing of Imaging Sensors and Cameras

The selection of a suitable sensor is an important step in the design of image processing systems. For the user, however, the choice is not always easy, as the information provided by different sensor manufacturers does not support a direct comparison of the available products. This problem has motivated the European Machine Vision Association to generate the EMVA 1288 standard. The parameters listed therein and the description of the measuring methods offer the user the necessary comparability in the selection of imaging sensors and cameras

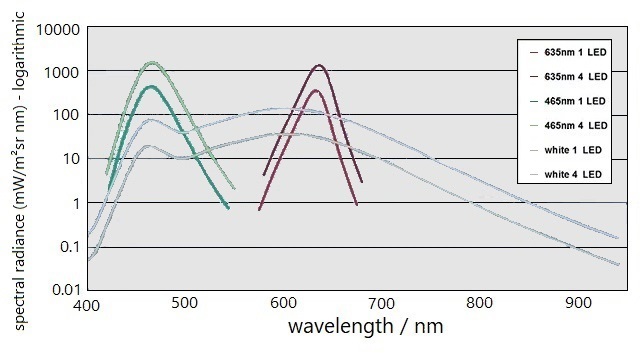

To measure sensitivity, linearity and non-uniformity (Photo Response Non Uniformity (PRNU)), the EMVA 1288 standard recommends that integrating sphere based light sources should be used as the reference [2]. As a special feature, the standard states that spheres must be configured with LED sources.

Compact Integrating Sphere Calibration Lamp for the Spectral Radiance (NMI used Calibration Standard)

The need for a compact spectral radiance calibration standard arises when the available space in or around the instrument to be calibrated is limited or from the need of a transfer standard or for service purposes. Depending on the application, additional requirements may arise in addition to the need for a compact version of integrating sphere.

An example of limited space availability is the calibration of fluorescence spectrophotometers with respect to the absolute spectral radiance sensitivity of the luminescence measurements. The development and characterization of the necessary spectral radiance transfer standard was carried out by Gigahertz-Optik GmbH and Physikalisch-Technische Bundesanstalt (PTB).

Reference Light Source for Sensitivity Adjustment of Combined Rain and Ambient Light Sensors

Integrating sphere light sources are widely used in the characterization and calibration of imaging sensors and cameras. In this application, the integrating sphere light source serves as a reference light source that can uniformly illuminate all of the many individual light-sensitive detectors (pixels). This enables the relative sensitivity of the pixels to be adjusted as required.

Quantifying the Veiling Glare of Imaging Systems

Veiling glare is most apparent when bright light spots or bright scenes are within the field of view of an imaging system. It is produced by unwanted scattered and reflected light from the image forming beam within the camera system that eventually impinges the image plane. It doesn’t form an image, but may be quite uniformly distributed resulting in image fogging and a reduction in image contrast. There are numerous causes of veiling glare including internal multiple reflections between the surfaces of lenses; scatter from lens imperfections; scatter and reflections from components and internal surfaces of the camera body; fluorescence; bulk scatter within lenses.

Reflectance Standards, Targets for LiDAR, Camera and Spectral Imaging

Spectral imaging and LiDAR sensing systems require white and greyscale reference reflectance targets for calibration and/or characterization. Highest homogeneity, durability, UV stability combined with highest reflectivity and lambertian reflection properties are requirements for such reference samples. We are able to offer customized solutions according to your needs. We use ODM is a high end optical material which is superior to other materials.