Quantifying the Veiling Glare of Imaging Systems

Veiling glare is most apparent when bright light spots or bright scenes are within the field of view of an imaging system. It is produced by unwanted scattered and reflected light from the image forming beam within the camera system that eventually impinges the image plane. It doesn’t form an image, but may be quite uniformly distributed resulting in image fogging and a reduction in image contrast. There are numerous causes of veiling glare including internal multiple reflections between the surfaces of lenses; scatter from lens imperfections; scatter and reflections from components and internal surfaces of the camera body; fluorescence; bulk scatter within lenses.

Quantifying Veiling Glare

By quantifying the veiling glare, also referred to as flare, the usable dynamic range of a camera can be increased. This requires a light source that can provide sufficiently high light-dark contrast.

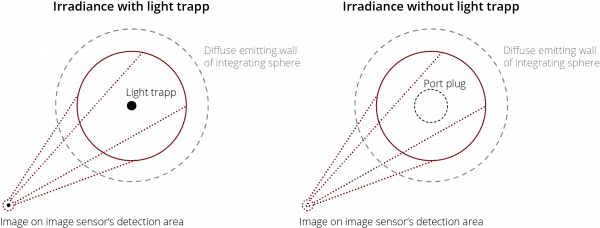

The standard ISO 9358 [1] defines veiling glare index (VGI) as the “ratio of the irradiance at the centre of the image of a small, circular, perfectly black area superimposed on an extended field of uniform radiance, to the irradiance at the same point of the image plane when the black area is removed.” VGI is usually expressed as a percentage. A good method of quantifying veiling glare is therefore based on an integrating sphere light source. This generates at its light exit port a uniform light field with diffuse, quasi-Lambertian radiation characteristics. Since the light field is larger than the lens diameter of the camera, the entire optics and thus the entire camera sensor are uniformly illuminated.

Measurement Setup Solution for Veiling Glare

In order to generate a contrast, a light trap is positioned on the opposite side of the sphere to the camera which is imaged by the camera sensor as a black area. Ideally, the signal from the ‘black’ area would be zero. However, this is not possible for two reasons:

- Due to veiling glare, stray light falls on the black image field;

2. The light trap is not perfect i.e. does not absorb all incident light completely.

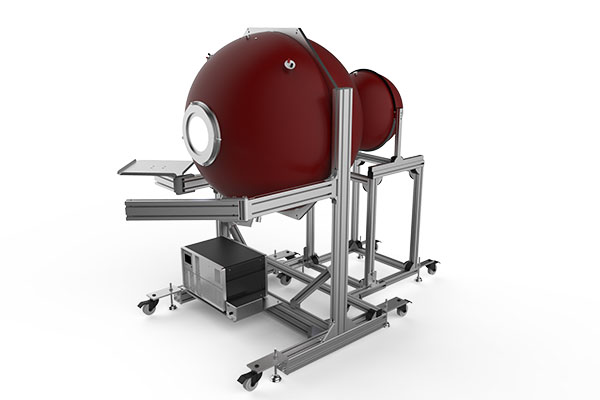

The quality of a light trap is determined by the complexity of its construction. In the simplest case, it is an area of matt black paint. In this case, the light absorption of the paint determines the degree of blackness. An improvement is offered by light traps that are designed from matt black coated tunnels with conical shaped internal surfaces. An even greater degree of absorption can be achieved with an Integrating sphere which is matt black coated on the inside. A measurement system is for example the ISS-100-LT.

The modular integrating sphere system from Gigahertz-Optik GmbH enables the configuration of custom solutions to meet even the most specific requirements. For example, a system for quantifying the veiling glare of space telescopes comprising a 100 cm diameter integrating sphere light source and a matching 50 cm diameter integrating sphere light trap was designed and configured to meet the application requirements using standard and special modules. An example is the fisheye camera calibration system ISS-50-LU-FE.

References

[1] ISO 9358 (1994): Optics and optical instruments– Veiling glare of image forming systems – Definitions and methods of measurement