7.4 UV Curing and UV Processing

UV curing is a process in which photo-curable chemicals applied to substrates are irradiated with high energy UV or visible radiation for curing. This energy accelerates polymerization (cross-linking) and consequently the hardening or drying process. The irradiated energy needs to be controlled since too low a dose will not cure the product, whereas too high a dose will damage it.

In the curing application, a dose refers to the amount of energy delivered to the target product. It is defined as radiant exposure (energy per unit area) and typically measured as irradiance over time.

J/cm2 = W/cm2 × seconds

High-power UV sources are used in this process. Because of non-linear ageing, UV output needs to be continuously monitored and controlled. These high UV levels place special demands on the measurement devices used in this application.

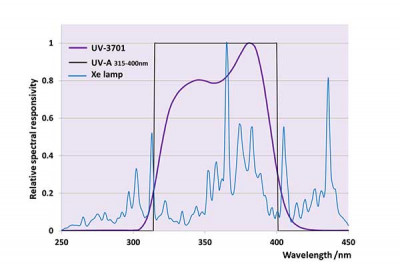

That component of ultraviolet energy useful for curing makes up only a small part of the spectral bandwidth within the lamp’s total emission spectrum and the bare detector‘s spectral sensitivity. Optical bandpass filters are therefore used to limit the detector‘s sensitivity to the spectral range of interest.

Fig. 1: UV curing spectral region

Conventionally designed UV irradiation detectors show drift and instability over time due to the hostile ambient conditions found in the UV-curing process. Solarization, ’fogging” effects and even delamination of the filter elements and other optical components can occur. In addition to altering the detector’s absolute sensitivity, these effects can also change its spectral sensitivity. On recalibration, a change in absolute sensitivity may be noted and adjusted but unless a complete spectral test is performed, a change in spectral sensitivity can go undetected. What is thought to be a newly recalibrated detector will often produce erroneous readings when returned to the end user.

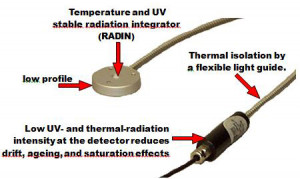

Fig. 2: UV curing detector

Fig. 2: UV curing detector

A new detector design has been developed based on the integrating element, RADIN™, which is not only able to withstand the high UV and temperature conditions of the UV-curing process, but can also maintain stability and measurement accuracy over long term use. Critical components in the detector are only exposed to a fraction of the direct irradiation. RADIN is a trade name of Gigahertz-Optik. The detector’s response which best matches the absorption spectrum of the photo-curable chemical in use is selected. This way, the detector spectrally emulates the product to be cured. The lamp(s) used in the system are selected by the equipment manufacturer for optimal curing within this active bandpass. When lamp replacement becomes necessary, the replacement lamps should have similar spectral and absolute output as the old ones so as not to invalidate the established process parameters.

It should be noted that in order to properly ‘frame’ the results, information on the spectral response function of the detector in use should be provided along with any statement of measured magnitude. UV detectors from different manufacturers can have very different spectral responses. This means that they will not read the same under the same test conditions.

Due to the many errors involved with UV measurement, even two detectors from the same manufacturer can have very different readings. Normally in the field, readings within ±10 % are considered acceptable in the UV-A range. Uncertainties get progressively worse as you move to shorter wavelengths. It is important to remember that the UV meter is after all a scientific instrument which is expected to perform reliably and repeatedly in very hostile environments.

Maintaining calibration cycles at the intervals recommended by the manufacturer is necessary. If unacceptable levels of change are seen on recalibration, the cycle time should be shortened (staircase method). This way you end up with a recalibration program tailored to your specific requirements.

It is also recommended to have a second instrument on hand that should be used only for an in-house calibration check of the working production unit(s).